LOPdM: A low-power on-device predictive maintenance system based on self-powered sensor and TinyML (TIM, IF=5.6)

Image credit: [chen et al.]

Image credit: [chen et al.]

Abstract

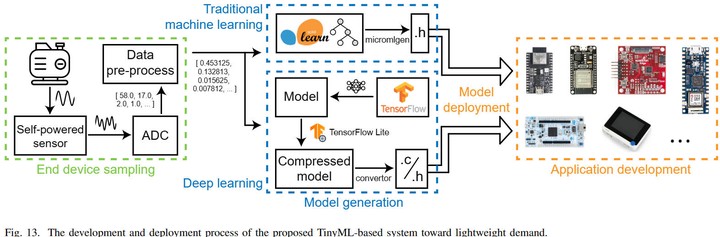

Recently, predictive maintenance (PdM) has emerged as a prominent strategy that can recognize the current status and predict future trends of machines, thereby preventing disastrous breakdowns. Such systems are mostly based on artificial intelligence (AI) models that run on resource-rich and power-hungry servers. Toward ultra-low-power, low-cost, and on-device inferring demands, in this study, we introduce a PdM system called LOPdM based on self-powered sensor (SPS) and tiny machine learning (TinyML) techniques. A rich SPS dataset has been collected in a simulated vibration environment and analyzed using six established AI models. Random forest (RF) and deep neural network (DNN) stand out given ultra-small data length, data number, and sampling rate with accuracy up to 99%. The trained model is then deployed on embedded systems for in-situ inferring and condition-based PdM. Power measurement has been conducted in detail to compare the systems relying on an inertial measurement unit (IMU) and an SPS. It has shown that the SPS-based system can save up to 66.8% of energy. An all-in-one prototype has been assembled and utilized for the field test, which proves a high accuracy for identifying malfunctions. As an interdisciplinary study, LOPdM provides valuable guidance for future ubiquitous AI applications.